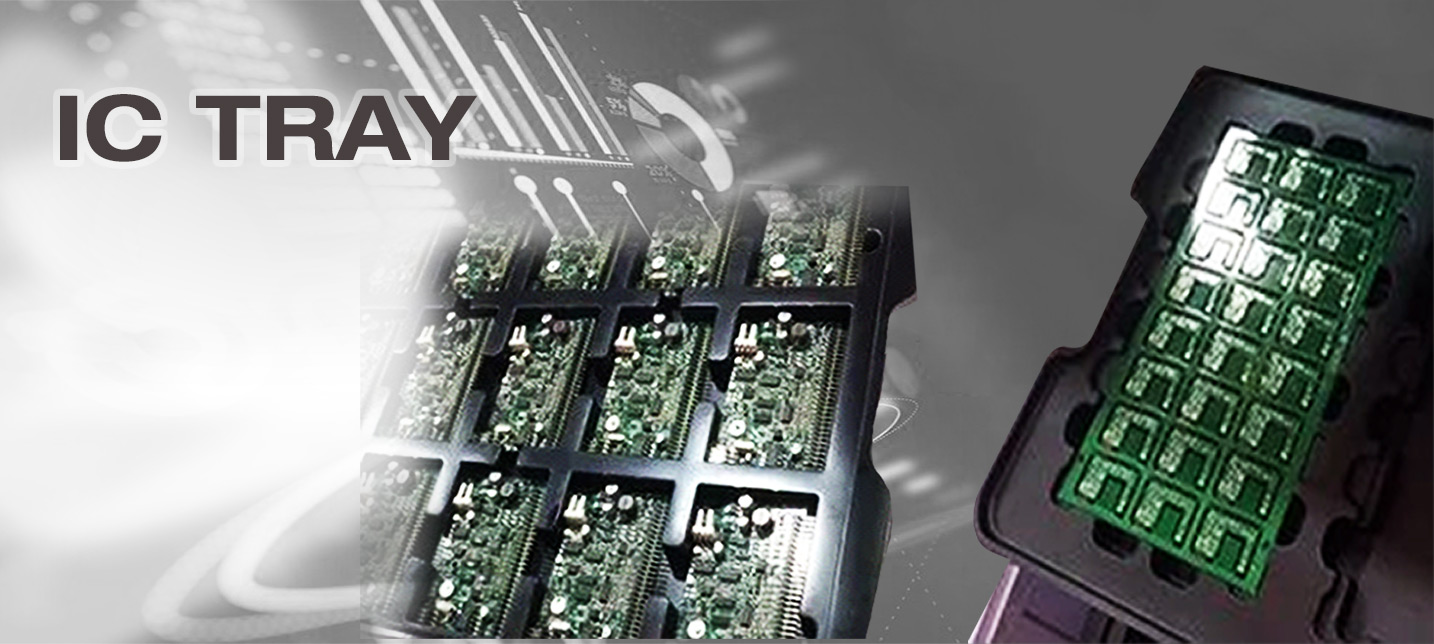

IC Tray (Vacuum Molded)

Introducing Mundo Co.’s IC tray

Overview

Mundo Co., we delivers vacuum forming tray to semiconductors and electronics industries as IC tray, parts tray which have features of antistatic and high quality of dimensional accuracy.

Applications

storing of devices such as electronic components and module products, in-process transport, protecting covers, blister packs for retail sales in Electronic devices (various ICs, image sensors, communication devices, optical devices, etc.)・Module products (power devices, lithium-ion batteries (LIB), camera modules, 5G communications, etc.)・Optical products (cover glass, lenses, laser diodes, etc.)・Medical (ampoules, medical equipment, storage of operating tools, etc.)

What are vacuum-formed trays?

The plastic film or sheet is heated and formed onto a mold with assist of vacuum adsorption to fit the mold. That is why the trays are called vacuum forming trays. They are also called soft trays because the plastic film used is soft. Also called parts tray, industrial tray and other names depending on the application. In common, they are also used for egg packaging, tofu packaging and food take away packaging because trays are can be produce in low cost depending on the packaging design and material used. At Mundo Co., we mainly use antistatic plastic film as part trays for semiconductors and electronics industry and we are capable to design and develop a tray that fit your application.

Merit to use vacuum forming tray

・Mold costs are significantly lower than injection mold.

・Faster production cycle than injection process.

・Multiple pieces can be produced from one mold, so product costs are low and delivery can be completed in a short time.

Disadvantages

・Because the material is a film or sheet, it is stretched and thickness control is difficult

・The front and back end up with the same shape.

・Compared to injection molding, it is difficult to achieve dimensional precision and strength.

However, Mundo Co., has been producing precise IC tray to semiconductor and electrics industry using our vacuum forming system with experienced technical ability. In addition, while trays are usually removed after molding, Mundo Co., has also Auto-trimming machine which allows increase the overall production outputs and reduce the loss time in production. Therefore, product cost will be lower and contribute competitive market price.

Depending on design and dimensional precision of the requirements Mundo Co., may also propose injection molding tray which Mundo also has machine with long experience.

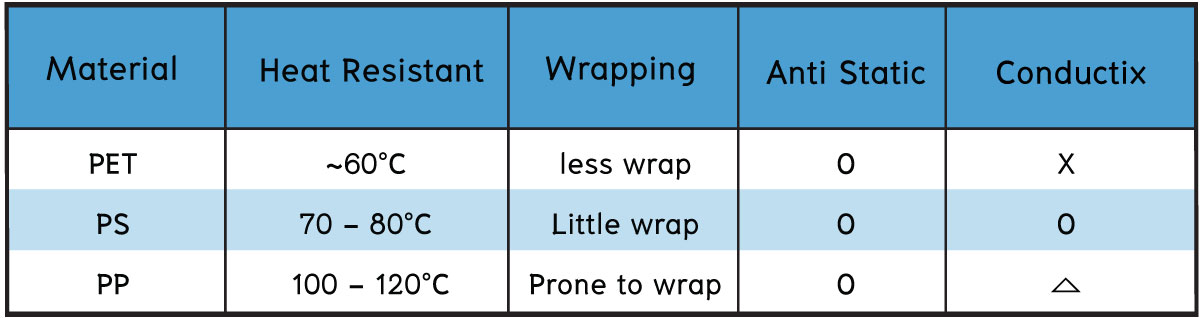

Vacuum Forming Tray Materials

General-purpose single-layer sheet